Isixhobo yenye yezona ndawo zibalulekileyo kumatshini wokwenza izixhobo.Ngophuhliso lwesayensi kunye nobuchwepheshe, isixhobo sitshintshile ukusuka kwisixhobo sokuqala se-alloy ukuya kwesona sixhobo sisetyenziswa ngokuqhelekileyo.Ukugaya kunye nokuphinda kufakwe i-carbide ene-cemented kunye nezixhobo zetsimbi ezikhawulezayo ziyinkqubo eqhelekileyo ngoku.Nangona ixabiso lesixhobo sokugaya okanye ukubuyisela kwakhona liyinxalenye encinci yeendleko zokwenziwa kwezixhobo ezitsha, linokwandisa ubomi besixhobo kunye nokunciphisa iindleko zokuvelisa.Inkqubo yokugaya kwakhona yindlela yonyango eqhelekileyo yezixhobo ezikhethekileyo okanye izixhobo ezibizayo.Izixhobo ezinokuthi zenziwe ngokutsha okanye zifakwe ngokutsha ziquka amasuntswana okomba, izisiki zokungqusha, iihobs kunye nezixhobo zokwenza.

Ukugaya isixhobo kwakhona

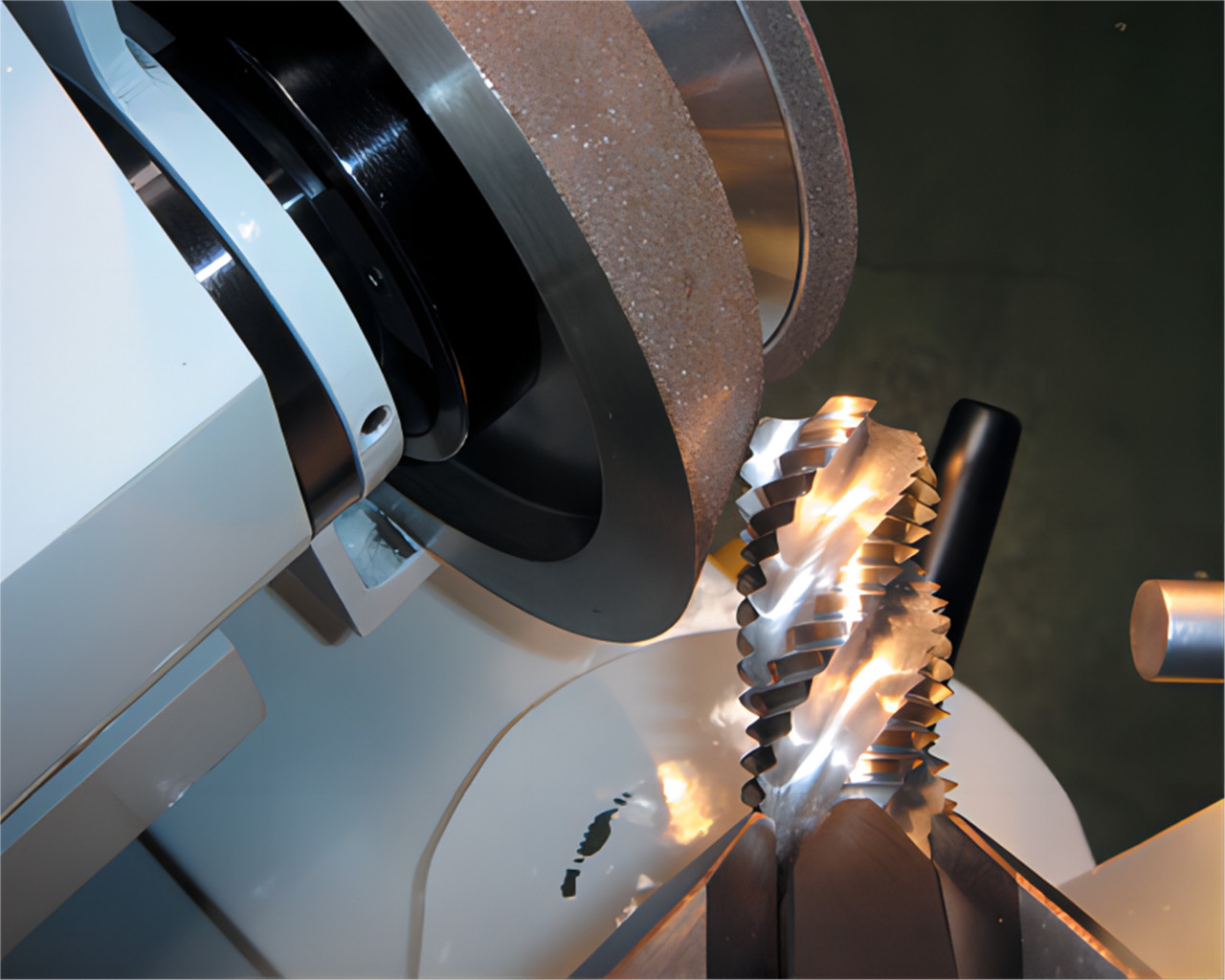

Kwinkqubo yokugaya i-drill okanye i-milling cutter, kuyimfuneko ukugaya umgca wokusika ukususa i-coating yasekuqaleni, ngoko ivili lokugaya elisetyenzisiweyo kufuneka libe nobunzima obaneleyo.Ukucutshungulwa kwangaphambili kwe-cut edge ngokugaya kwakhona kubaluleke kakhulu.Akuyimfuneko kuphela ukuqinisekisa ukuba imilo yejometri ye-edge yokuqala yokusika inokugcinwa ngokupheleleyo kwaye ngokuchanekileyo emva kokugaya isixhobo, kodwa ifuna ukuba isixhobo esifakwe kwi-PVD kufuneka sibe "sikhuselekileyo" sokugaya kwakhona.Ngoko ke, kuyimfuneko ukuphepha inkqubo yokugaya engafanelekanga (njengokugaya okanye ukugaya okomileyo, apho umphezulu wesixhobo wonakaliswa ngenxa yokushisa okuphezulu).

Ukususwa kwengubo

Ngaphambi kokuba isixhobo siphinde sifakwe kwakhona, zonke iingubo zangaphambili zingasuswa ngeendlela zekhemikhali.Indlela yokususa iikhemikhali isoloko isetyenziselwa izixhobo ezintsonkothileyo (ezifana ne-hobs kunye ne-broaches), okanye izixhobo ezine-recoating ezininzi kunye nezixhobo ezineengxaki ezibangelwa bubunzima bokugquma.Indlela yokususwa kweekhemikhali yokugqoka ivame ukukhawulelwa kwizixhobo zetsimbi ezikhawulezayo, kuba le ndlela iya konakalisa i-carbide substrate ene-cemented: indlela yokususwa kweekhemikhali yokucoca iyakucoca i-cobalt kwi-samente ye-carbide substrate, ekhokelela kwi-porosity yomhlaba. i-substrate, ukubunjwa kwee-pores kunye nobunzima bokubuyisela kwakhona.

"Indlela yokususa i-Chemical ikhethwa ukususwa kwe-corrosion ye-coatings eqinile kwintsimbi ephezulu."Ngenxa yokuba i-matrix ye-carbide ene-cemented iqulethe iikhemikhali zekhemikhali ezifana nezo zifakwe kwi-coating, i-solvent yokususa iikhemikhali inokuthi yonakalise i-matrix ye-carbide ene-cemented kune-high-speed steel matrix.

Ukongeza, kukho iindlela zekhemikhali ezinelungelo elilodwa lomenzi wechiza ezifanelekileyo zokususa i-PVD yokwambathisa.Kwezi ndlela zeekhemikhali, kukho ukusabela okuncinci kweekhemikhali phakathi kwesisombululo sokususa i-coating kunye ne-cemented carbide matrix, kodwa ezi ndlela azizange zisetyenziswe ngokubanzi ngoku.Ukongezelela, kukho ezinye iindlela zokucoca i-coating, ezifana ne-laser processing, i-abrasive blasting, njl. Indlela yokususa iikhemikhali yindlela eqhelekileyo, kuba inokubonelela ngokufana okulungileyo kokukhutshwa kwendawo.

Okwangoku, inkqubo yokubuyisela eqhelekileyo kukususa isambatho sokuqala sesixhobo ngokusebenzisa inkqubo yokugaya.

Uqoqosho lokubuyisela kwakhona

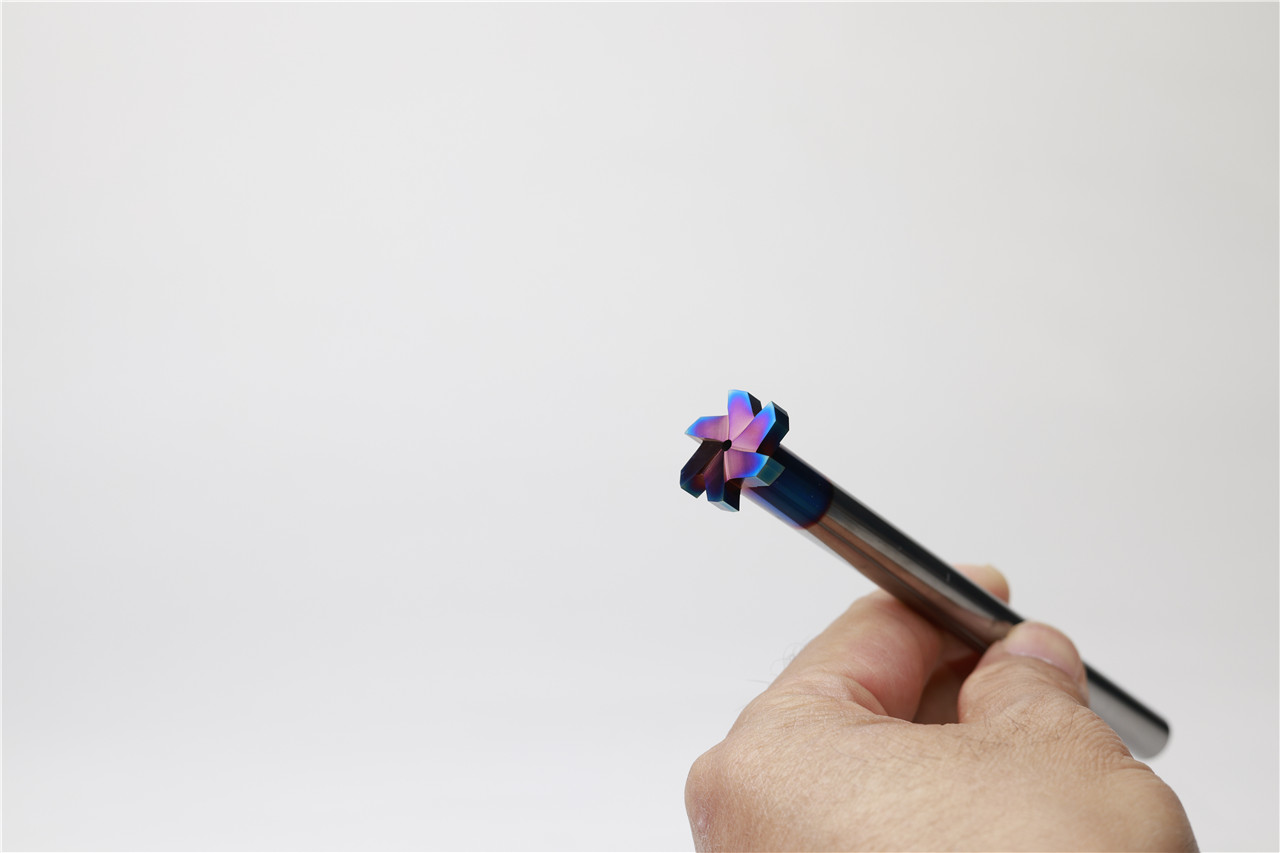

Ezona zinto zixhaphakileyo zokugquma izixhobo yiTiN, TiC kunye neTiAlN.Ezinye ii-superhard nitrogen/carbide coatings nazo zisetyenzisiwe, kodwa azixhaphakanga kakhulu.Izixhobo ezigqunywe ngedayimani yePVD nazo zinokuphinda ziphinde ziqatywe.Ngexesha lokuphinda uphahla, isixhobo siya "kukhuselwa" ukuphepha umonakalo kwindawo ebalulekileyo.

Oku kudla ngokuba njalo: emva kokuthenga izixhobo ezingagqunywanga, abasebenzisi banokuzigquma xa zifuna ukuhlalwa phantsi, okanye basebenzise iingubo ezahlukeneyo kwizixhobo ezitsha okanye izixhobo zokubuyisela.

Ukulinganiselwa kwakhona

Kanye njengoko isixhobo sinokuphinda sibuyiselwe amaxesha amaninzi, umphetho wokusika wesixhobo unokugqunywa amaxesha amaninzi.Isitshixo sokuphucula ukusebenza kwesixhobo kukufumana i-coating ngokubambelela kakuhle kumphezulu wesixhobo esiye safunyanwa.

Ngaphandle komgca wokusika, indawo eseleyo yesixhobo ayinakudinga ukuba ifakwe okanye ihlaziywe ngexesha lokugaya isixhobo ngasinye, kuxhomekeke kuhlobo lwesixhobo kunye neeparitha zokusika ezisetyenziswe kwi-machining.I-Hobs kunye ne-broaches zixhobo ezifunekayo ukususa yonke i-coating yasekuqaleni xa uhlaziywa, ngaphandle koko ukusebenza kwesixhobo kuya kuncitshiswa.Ngaphambi kokuba ingxaki yokubambelela ebangelwa uxinzelelo ibe yinto evelele, isixhobo sinokuphinda siphindwe ngamaxesha ambalwa ngaphandle kokususa isambatho esidala.Nangona i-PVD i-coating ine-residual compressive stress iluncedo ekusikeni kwesinyithi, olu xinzelelo luya kunyuka ngokunyuka kobunzima bokugquma, kwaye i-coating iya kuqala ukucima emva kokugqithisa umda omiselweyo.Xa uhlaziywa ngaphandle kokususa isambatho esidala, ubukhulu buyongezwa kububanzi obungaphandle besixhobo.Kwi-drill bit, kuthetha ukuba i-diameter yomngxuma iya iba nkulu.Ngoko ke, kuyimfuneko ukuqwalasela impembelelo yobunzima obongezelelweyo bokugquma kwi-diameter yangaphandle yesixhobo, kunye nefuthe lezi zimbini kwi-dimensional tolerance of the machined hole diameter.

I-drill bit ingagqunywa amaxesha ama-5 ukuya kwali-10 ngaphandle kokususa i-coating endala, kodwa emva koko iya kujongana neengxaki ezinzulu.UDennis Klein, usekela mongameli weSpecial Tools, wayekholelwa ukuba ubukhulu bokugquma abuyi kuba yingxaki phakathi koluhlu lwempazamo lwe ± 1 µ m;Nangona kunjalo, xa impazamo ingaphakathi koluhlu lwe-0.5 ~ 0.1 µ m, impembelelo yobuninzi be-coating kufuneka ithathelwe ingqalelo.Logama nje ubukhulu bokugquma bungabi yingxaki, izixhobo eziqhathiweyo kunye nezixhobo eziphantsi komhlaba zinokusebenza ngcono kunezo zakuqala.

Ixesha lokuposa: Feb-24-2023