Yintoni umahluko kunye nomahluko phakathi HSS milling cutters kunye Carbide milling cutters ngokwemathiriyeli, isakhiwo, kunye nokusebenza?Kweziphi iimeko zomatshini kufuneka kusetyenziswe izixhobo zeHSS, kwaye kweziphi iimeko apho kufuneka kusetyenziswe izixhobo zeCarbide?

1. Umahluko phakathi kwe-HSS End Mill kunye neTungsten Carbide End Mill

1. Umahluko kwizinto eziphathekayo.

I-HSS End Mill yenziwe ngeentsimbi zetsimbi ezikhawulezayo, ngokuqhelekileyo zenziwe nge-M42 eziphathekayo, kunye nomxholo we-vanadium ongekho ngaphezu kwe-1% kunye nomxholo we-cobalt we-8%.

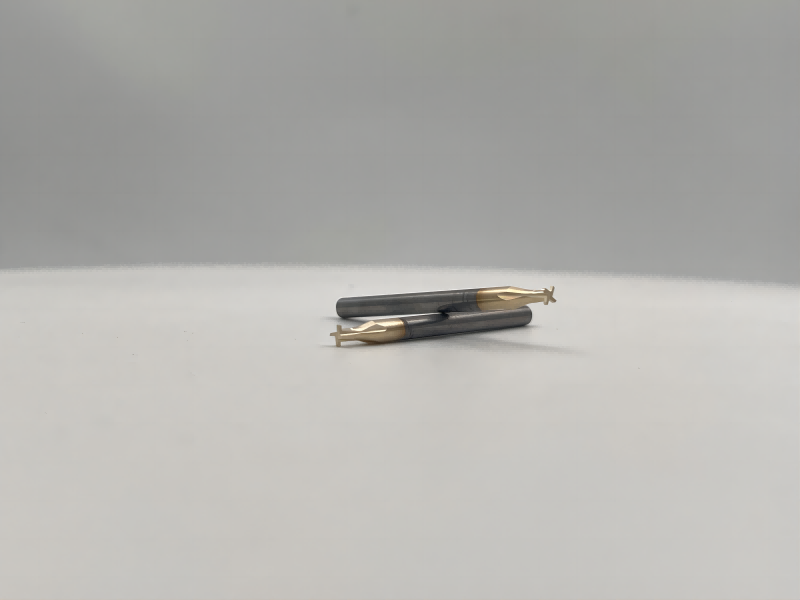

Carbide End Mill sisixhobo se-CNC esenziwe nguTungsten Carbide.

2. Umahluko ekusebenzeni kokusebenza.

Izixhobo zokusika i-HSS zinobulukhuni beqondo lokushisa kwe-62-70HRC, ngelixa izixhobo zokusika i-carbide zinobunzima beqondo lokushisa kwe-89-94HRC.Ukumelana nobushushu bomgangatho wesixhobo kufikelela kwi-1000 ℃, kwaye isantya sokusika i-carbide sinokunyuswa ngo-50-100% xa kuthelekiswa ne-HSS.Ukuqina kwesixhobo kunokuphuculwa ngamaxesha angama-2-10;Xa kuthelekiswa nezixhobo zokusika ze-HSS, izixhobo zokusika i-carbide zifanelekile ngakumbi kwisantya esiphezulu, esisebenzayo, kunye nokushisa okuphezulu.

izixhobo zokusika i-carbideIndawo ephezulu yokunyibilika, ubunzima obuphezulu, imodyuli ephezulu ye-elastic, uzinzo oluhle lweekhemikhali kunye nokuzinza kwe-thermal.Ukuqina kwayo, ukumelana nokunxiba kunye nokumelana nobushushu kungcono kakhulu kunezixhobo zokusika ze-HSS.

Ubunzima: Isixhobo seCarbide 89 ~ 94HRC.Izixhobo ze-HSS 62-70HRC.

Ukumelana nobushushu: Izixhobo zeCarbide kwi-800-1000 ℃, izixhobo ze-HSS kwi-600-650 ℃.

Ukunxiba ukuxhathisa: Ukuxhatshazwa kwezixhobo zeCarbide ngamaxesha angama-15-20 kwezixhobo ze-HSS.

Isantya sokusika: Isantya sesixhobo seCarbide ngamaxesha angama-4-10 kweso sixhobo seHSS.

2. Kuya kuba nini HSS milling cutters kunyeCarbide milling cutterszisetyenziswe?

Ayizizo zonke iimeko zokucutshungulwa ezifuna ukusetyenziswa kweCarbide milling cutters, njengoko ulawulo lweendleko zenkqubo nganye yokucubungula iyahluka, kwaye izixhobo ezahlukeneyo zokusika zingasetyenziswa ngokuguquguqukayo.

Xa ubunzima be-machining buphantsi, iimfuno zokuchaneka komatshini aziphezulu, kwaye izixhobo zomatshini eziphantsi zisetyenzisiweyo, ubuninzi beemveliso zincinci, kwaye inzuzo iphantsi, izixhobo zokusika ze-HSS zingasetyenziswa.Nokuba kunzima ukwenza izixhobo zoomatshini, izixhobo ze-HSS zinokuba nobuchule, kodwa isantya sokusika, ukuxhathisa, kunye nokuqina akwanelanga.

Ndicinga ukuba kwiimeko ezininzi, ngakumbi ngexesha le-speed-speed, esebenzayo, kunye ne-machining enkulu, kuyimfuneko ngakumbi ukusebenzisa izixhobo zokusika i-carbide, kunye nezixhobo ze-ceramic kunye nedayimani: ixabiso eliphezulu lesixhobo esisodwa alithethi ukuba iindleko eziphezulu zokulungisa. ;Kwiimeko ezininzi, ukusebenzisa izixhobo "zamaxabiso aphezulu" kubangela iindleko eziphantsi zokulungisa kunezixhobo ze-HSS.

Ixesha lokuposa: Jun-03-2023