Ngophuhliso lwenzululwazi yanamhlanje kunye nobuchwepheshe, izixhobo zobunjineli ezingakumbi ezinobunzima obuphezulu zisetyenziswa, ngelixa itekhnoloji yemveli yokujika ayinabuchule okanye ayinakufezekisa ukusetyenzwa kwezinto ezinobulukhuni obuphezulu konke konke.I-carbide edibeneyo, i-ceramics, i-PCBN kunye nezinye izixhobo ze-superhard zinobulukhuni obuphezulu beqondo lokushisa, ukuxhathisa ukunxiba kunye nokuzinza kwe-thermochemical, ezibonelela ngeyona nto ifunekayo yokusikwa kwezinto ezinobunzima obuphezulu, kwaye zizuze izibonelelo ezibalulekileyo kwimveliso.Izinto ezisetyenziswa sisixhobo esinzima kakhulu kunye nesakhiwo saso sesixhobo kunye neeparitha zejometri zizinto ezisisiseko zokuqonda ukujika okunzima.Ke ngoko, indlela yokukhetha izixhobo zesixhobo esinzima kakhulu kunye nokuyila ulwakhiwo olufanelekileyo lwesixhobo kunye neeparamitha zejometri ibalulekile ukufezekisa ukujika okuzinzileyo!

(1) I-carbide efakwe ngesamente

Faka isicelo esisodwa okanye ngaphezulu kwe-TiN, i-TiCN, i-TiAlN kunye ne-Al3O2 ngokuxhathisa okulungileyo kwizixhobo ze-carbide ezine-samente ezinobunzima obuhle, kunye nobukhulu bengubo yi-2-18 μ m.Ukugquma ngokuqhelekileyo kune-conductivity ephantsi kakhulu ye-thermal kune-substrate yesixhobo kunye nempahla yokusebenza, eyenza buthathaka umphumo we-thermal we-substrate yesixhobo;Ngakolunye uhlangothi, kunokuphucula ngokufanelekileyo ukungqubuzana kunye nokubambelela kwindlela yokusika kunye nokunciphisa isizukulwana sokusika ukushisa.

Nangona i-PVD yokwambathisa ibonisa iingenelo ezininzi, ezinye iingubo ezifana ne-Al2O3 kunye nedayimane zidla ngokuthatha itekhnoloji yokwaleka iCVD.I-Al2O3 luhlobo lokugquma olunokumelana nobushushu obuqinileyo kunye nokumelana ne-oxidation, enokwahlula ubushushu obuveliswa ngokusika kwisixhobo esithile.Itekhnoloji yokugqoka i-CVD inokuphinda idibanise iingenelo zeengubo ezahlukeneyo zokufezekisa umphumo obalaseleyo wokusika kunye nokuhlangabezana neemfuno zokusika.

Xa kuthelekiswa nezixhobo ze-carbide ezine-cemented, izixhobo ze-carbide ezifakwe nge-cemented ziphuculwe kakhulu kumandla, ukuqina kunye nokumelana nokunxiba.Xa ujika i-workpiece ngobulukhuni be-HRC45~55, i-carbide enesamente enexabiso eliphantsi inokubona ukujika kwesantya esiphezulu.Kwiminyaka yakutshanje, abanye abavelisi baye baphucula ukusebenza kwezixhobo ezigqunyiweyo ngokuphucula izinto zokugqoka kunye nezinye iindlela.Umzekelo, abanye abavelisi eUnited States naseJapan basebenzisa i-Swiss AlTiN impahla yokugquma kunye neteknoloji entsha yokugquma i-patent ukuvelisa iiblade ezigqunywe ngobulukhuni obuphezulu njenge-HV4500 ~ 4900, ezinokusika i-HRC47 ~ 58 die steel ngesantya esingama-498.56m/min. .Xa ubushushu bokuguqula bufikelela kwi-1500 ~ 1600 ° C, ubunzima abunciphi kwaye abuyi-oxidize.Ubomi benkonzo ye-blade buphindwe kane kwi-blade coated blade, ngelixa ixabiso li-30% kuphela, kwaye ukunamathela kuhle.

(2) I-Ceramicmaterial

Ngokuphuculwa okuqhubekayo kokubunjwa kwayo, ukwakheka kunye nenkqubo yokucinezela, ngokukodwa ukuphuhliswa kwe-nanotechnology, izixhobo ze-ceramic izixhobo zenza kube lula ukuqinisa izixhobo ze-ceramic.Kwixesha elizayo elingekude, ii-ceramics zinokubangela ukuguqulwa kwesithathu ekusikeni emva kwesinyithi esinesantya esiphezulu kunye ne-cemented carbide.Izixhobo zeCeramic zineenzuzo zobunzima obuphezulu (HRA91 ~ 95), amandla aphezulu (amandla okugoba 750 ~ 1000MPa), ukumelana nokunxiba kakuhle, ukuzinza kweekhemikhali okulungileyo, ukuxhathisa okulungileyo kokubambelela, i-coefficient ephantsi ye-friction kunye nexabiso eliphantsi.Ayisiyiyo loo nto kuphela, izixhobo ze-ceramic zikwanobunzima obuphezulu bobushushu obuphezulu, obufikelela kwi-HRA80 kwi-1200 ° C.

Ngexesha lokusika okuqhelekileyo, isixhobo se-ceramic sinokuqina okuphezulu kakhulu, kwaye isantya saso sokusika sinokuba ngama-2 ~ 5 amaxesha aphezulu kune-carbide ene-cemented.Kufanelekile ngokukodwa ukwenza izinto ezinobunzima obuphezulu, ukugqiba kunye ne-high-speed machining.Inokusika iintsimbi ezohlukeneyo eziqinileyo kunye nentsimbi etyhidiweyo eqinileyo enobulukhuni ukuya kuthi ga kwi-HRC65.Ngokuqhelekileyo zisetyenziswa iiseramikhi ezisekwe kwi-alumina, i-silicon nitride esekwe kwiiseramics, iicermets kunye ne-whisker tougher ceramics.

Izixhobo ze-ceramic ezisekelwe kwi-alumina zinobunzima obubomvu obuphezulu kune-carbide enesamente.Ngokuqhelekileyo, umgca wokusika awuyi kuvelisa i-deformation yeplastiki phantsi kweemeko zokusika ngesantya esiphezulu, kodwa amandla kunye nokuqina kwayo kuphantsi kakhulu.Ukuze kuphuculwe ukuqina kwayo kunye nokuchasana kwempembelelo, i-ZrO okanye i-TiC kunye ne-TiN umxube unokongezwa.Enye indlela yokongeza intsimbi ecocekileyo okanye i-silicon carbide whiskers.Ukongeza kubulukhuni obubomvu obuphezulu, i-silicon nitride esekwe kwi-ceramics inokuqina okuhle.Xa kuthelekiswa ne-alumina esekelwe kwi-ceramics, ukungona kwayo kukuba kulula ukuvelisa ukusasazwa kobushushu obuphezulu xa kusetyenzwa intsimbi, eyenza kube nzima ukunxiba izixhobo.Iiseramikhi ezisekwe kwi-silicon nitride zisetyenziswa ikakhulu ekujikeni okwethutyana kunye nokusila intsimbi engwevu.

I-Cermet luhlobo lwezinto ezisekelwe kwi-carbide, apho i-TiC iyona nqanaba elinzima (0.5-2 μm) Zidibaniswe ne-Co okanye i-Ti binders kwaye zifana nezixhobo ze-carbide ze-cemented, kodwa zinobudlelwane obuphantsi, ukungqubuzana okulungileyo kunye nokulungileyo. nxiba ukumelana.Inokumelana nobushushu obuphezulu bokusika kune-carbide yesamente eqhelekileyo, kodwa ayinayo impembelelo yokumelana ne-carbide enesamente, ukuqina ngexesha lokusika okunzima kunye namandla ngesantya esiphantsi kunye nokutya okukhulu.

(3) Cubic boron nitride (CBN)

I-CBN yeyesibini kuphela kwidayimane kubunzima kunye nokumelana nokunxiba, kwaye inobunzima obuphezulu bobushushu obubalaseleyo.Xa kuthelekiswa neekeramics, ukuxhathisa ubushushu kunye nokuzinza kweekhemikhali kubi kancinci, kodwa amandla empembelelo kunye nokusebenza okuchasene nokutyumza kungcono.Kusetyenziswa ngokubanzi ukusika intsimbi eqinile (HRC ≥ 50), i-pearlitic grey cast iron, i-chilled cast iron kunye ne-superalloy.Xa kuthelekiswa nezixhobo ze-carbide eziqiniweyo, isantya sayo sokusika sinokunyuswa ngomyalelo omnye wobukhulu.

Isixhobo esihlanganisiweyo se-polycrystalline cubic boron nitride (PCBN) esinomxholo ophezulu we-CBN sinobunzima obuphezulu, ukumelana nokunxiba kakuhle, amandla aphezulu oxinzelelo kunye nokuqina kwempembelelo entle.Ukungalungi kwayo kukungazinzi kakuhle kwe-thermal kunye ne-inertness ephantsi yeekhemikhali.Kufanelekile ukusika i-alloys ekwazi ukumelana nobushushu, isinyithi esityhidiweyo kunye neentsimbi ezisekelwe kwintsimbi.Umxholo wamasuntswana e-CBN kwizixhobo ze-PCBN uphantsi, kwaye ubulukhuni bezixhobo ze-PCBN ezisebenzisa i-ceramics njenge-binder ziphantsi, kodwa zenza ukuzinza okungahambi kakuhle kwe-thermal kunye ne-inertia ephantsi yeekhemikhali zezinto zangaphambili, kwaye ifanelekile ukusika intsimbi eqinile.

Xa usika isinyithi esimpunga kunye nentsimbi eqinile, isixhobo se-ceramic okanye isixhobo se-CBN sinokukhethwa.Ngenxa yesi sizathu, indleko-inzuzo kunye nohlalutyo lomgangatho wokucubungula kufuneka lwenziwe ukugqiba ukuba yeyiphi enye ongayikhetha.Xa ubulukhuni bokusika bungaphantsi kwe-HRC60 kwaye isantya esincinci sokutya samkelwe, isixhobo se-ceramic lukhetho olungcono.Izixhobo ze-PCBN zilungele ukusika ii-workpieces ezinobunzima obungaphezulu kwe-HRC60, ingakumbi kumatshini ozenzekelayo kunye nokuchaneka okuphezulu.Ukongeza, uxinzelelo olushiyekileyo kumphezulu womsebenzi emva kokusikwa ngesixhobo sePCBN lukwazinzile noko kuneso sixhobo seceramic phantsi kwemeko yokunxiba kweflank efanayo.

Xa usebenzisa isixhobo se-PCBN ukomisa intsimbi eqiniweyo, le migaqo ilandelayo kufuneka ilandelwe: khetha ubunzulu obukhulu bokusika kangangoko kunokwenzeka phantsi komqathango wokuba ukuqina kwesixhobo somatshini kuvumela, ukuze ubushushu obuveliswe kwindawo yokusika bukwazi ukuthambisa. intsimbi ephambi komphetho wendawo, enokunciphisa ngokufanelekileyo ukunxiba kwesixhobo sePCBN.Ukongeza, xa usebenzisa ubunzulu obuncinci bokusika, kufuneka kwakhona kuthathelwe ingqalelo ukuba ukungahambi kakuhle kwe-thermal yesixhobo sePCBN kunokwenza ubushushu kwindawo yokusika kade ukuba busasazeke, kwaye indawo yokucheba inokuvelisa isiphumo esicacileyo sokuthambisa isinyithi, ukunxiba kokuphela.

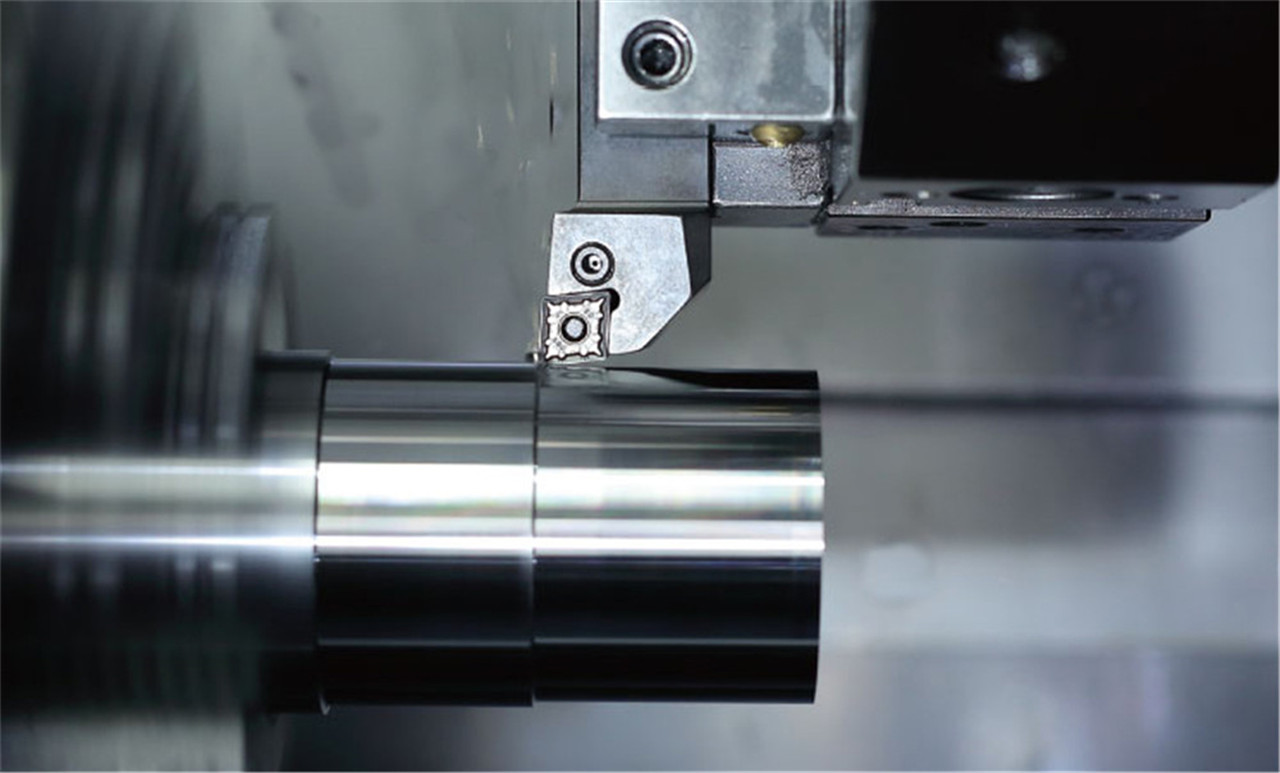

2. Isakhiwo se-blade kunye neeparitha zejometri zezixhobo ezinzima kakhulu

Ukuzimisela okunengqiqo kwimilo kunye neeparitha zejometri zesixhobo kubaluleke kakhulu ukunika umdlalo opheleleyo ekusebenzeni kokusika kwesixhobo.Ngokumalunga namandla isixhobo, isixhobo incam amandla iimilo incakuba ezahlukeneyo ukusuka phezulu ukuya ezantsi: ngeenxa zonke, 100 ° idayimani, square, 80 ° idayimani, unxantathu, 55 ° diamond, 35 ° diamond.Emva kokuba kukhethwe i-blade, i-blade shape enamandla kakhulu iya kukhethwa.Iincakuba ezijika nzima kufuneka nazo zikhethwe zibe nkulu kangangoko, kwaye ukwenziwa komatshini orhabaxa kufuneka kwenziwe ngeencakuba zearc radius ezijikelezayo nezinkulu.Incam yeradiyasi ye-arc imalunga ne-0.8 xa ugqiba μ Malunga ne-m.

Iitshiphu zetsimbi eziqinileyo zibomvu kunye neerebhoni ezithambileyo, ezinobunzima obukhulu, obulula ukuphuka kunye nokungabophi.Indawo yokusika insimbi eqinile inomgangatho ophezulu kwaye ngokuqhelekileyo ayivelisi i-chip accumulation, kodwa amandla okusika makhulu, ngokukodwa amandla okusika i-radial makhulu kunamandla amakhulu okusika.Ngoko ke, isixhobo kufuneka sisebenzise i-angle yangaphambili embi (hamba ≥ - 5 °) kunye ne-angle enkulu yangasemva (ao = 10 ° ~ 15 °).I-angle yokuphambuka engundoqo ixhomekeke kubungqongqo besixhobo somatshini, ngokubanzi i-45 ° ~ 60 °, ukunciphisa incoko ye-workpiece kunye nesixhobo.

Ixesha lokuposa: Feb-24-2023