Njengoko kusaziwa, ukubuyisela kwakhona yinkqubo yokugqibela kwinkqubo yomngxuma.Ukuba izinto ezithile ziyayichaphazela, kunokwenzeka ukuba iimveliso ezigqityiweyo ezifanelekileyo ziya kuba yinkunkuma ngoko nangoko.Yintoni ke esimele siyenze xa sinengxaki?Izixhobo zokusika ze-OPT ziququzelele imiba ethile kunye nemilinganiselo evela kwisicelo esisebenzayo se-Reamer, ngethemba lokuba unokufumana ulwazi oluthile kwinqaku.

1. Uburhabaxa obubi bomngxuma ongaphakathi

isizathu

1.Isantya sokusika siphezulu kakhulu.

2.Ukukhethwa kwe-Cutting fluid ayifanelekanga.

3.I-angle yokutenxa ephambili ye-reamer inkulu kakhulu, kwaye i-cut cut ye-reamer ayikho kwi-circumference efanayo.

4.Isibonelelo sokubuyisela kwakhona sikhulu kakhulu, asilingani okanye sincinci kakhulu, kwaye umphezulu wendawo awulungiswanga.

I-5.Ukuphambuka kwe-swing yecandelo lokusika le-reamer lidlula ukunyamezela, ukusika akubukhali, kwaye umphezulu unzima.

6.Umphetho wokusika we-reamer ubanzi kakhulu.

7.Ukususwa kwetshiphu engalunganga ngexesha lokubuyisela kwakhona.

8.Ukugqithisa okugqithisileyo kwe-reamer.

9.I-remer igruzukile, ishiya i-burrs okanye i-chips kwi-edge.

10.Kukho ukwakhiwa kwenkunkuma kwinqanaba lokusika.

11.Ngenxa yezithintelo zezinto eziphathekayo, ayifanelekanga i-zero degree okanye i-reamers ye-rake engalunganga.

Amanyathelo okuphendula

1. Ukunciphisa isantya sokusika.

2. Khetha Ukusika ulwelo ngokwezixhobo zokusetyenzwa.

3. Nciphisa i-angle ephambili yokuphambuka ngokufanelekileyo kwaye ugaye i-cut cut edge ngokuchanekileyo.

4. Nciphisa isibonelelo sokubuyisela kwakhona ngokufanelekileyo.

5. Ukuphucula ukuchaneka kunye nomgangatho wendawo yomngxuma ongaphantsi ngaphambi kokuba uphinde uphinde uphinde unyuse isibonelelo sokubuyisela kwakhona.

6. Gaya ububanzi bebhanti ye-blade.

7. Nciphisa inani lamazinyo kwi-reamer ngokwemeko ethile, ukwandisa indawo ye-chip yokubamba i-groove, okanye usebenzise i-reamer ene-angle inclination angle ukuqinisekisa ukususwa kwe-chip egudileyo.

8. Ukutshintsha rhoqo i-reamer kwaye ususe indawo yokugaya ngexesha lokugaya i-blade.

9. Ngexesha lokugaya, ukusetyenziswa, kunye nokuthuthwa kwe-reamer, amanyathelo okukhusela kufuneka athathwe ukuphepha ukungqubana.

10. Kwi-remer eyonakeleyo, sebenzisa i-oilstone ecolekileyo ukuyilungisa okanye ukuyibuyisela endaweni yayo.

2. Umngxuma ongaphakathi ongqukuva

isizathu

1. I-remer inde kakhulu kwaye ayinakho ukuqina, okubangela ukungcangcazela ngexesha lokubuyisela kwakhona.

2. I-angle yokutenxa ephambili ye-reamer incinci kakhulu.

3. Umgca wokusika we-reamer umxinwa.

4. Isibonelelo sokubuyisela kwakhona ngokugqithisileyo.

5. Kukho iinotshi kunye nemingxuma enqamlezileyo kumphezulu womngxuma ongaphakathi.

6. Kukho imingxuma yesanti kunye nemingxuma kumphezulu womngxuma.

7. Ibherethi yokusonta ikhululekile, akukho mkhono wesikhokelo, okanye ukucoceka phakathi kwe-reamer kunye nomkhono wesikhokelo mkhulu kakhulu, okanye i-workpiece ikhubazekile emva kokususwa ngenxa yokubamba okuqinileyo kwee-workpieces ezinodonga olubhityileyo.

Amanyathelo okuphendula

1. IiReamers ezinobungqongqo obunganelanga zinokusebenzisa izixhobo zokuphinda zisebenze ngokulingana kwamazinyo, kwaye ukufakelwa kwe-reamer kufuneka kusebenzise ukudibanisa okuqinileyo ukunyusa i-angle yokutenxa ephambili.

2. Khetha i-reamers ezifanelekileyo kwaye ulawule ukunyamezelwa kwesithuba somngxuma wenkqubo yangaphambili.Ukusebenzisa ii-pitch reamers ezingalinganiyo kunye nokusebenzisa imikhono yesikhokelo emide nangaphezulu;Khetha iindawo ezingenanto.

3.Xa usebenzisa i-pitch reamers elinganayo ukukhupha imingxuma echanekileyo, ukucocwa kwe-spindle yesixhobo somatshini kufuneka kuhlengahlengiswe, kwaye ucoceko olufanelekileyo lomkhono wesikhokelo kufuneka lube phezulu okanye iindlela ezifanelekileyo zokubambelela kufuneka zisetyenziswe ukunciphisa amandla okubamba.

3. Umgca ophakathi awuthe tye

isizathu

1. Ukutenxa kokugrumba ngaphambi kokuphinda kuphinde kuphinde kuphinde kuphinde kuphinde kuphindeke, ngakumbi xa i-aperture incinci, ayinako ukulungisa ukugoba kwasekuqaleni ngenxa yokungaqini kakuhle kwe-reamer.

2. I-angle yokutenxa ephambili ye-remer inkulu kakhulu;Isikhokelo esilambathayo senza kube lula kulowo uphinda ajike endleleni ngexesha lokubuyisela kwakhona.

3. Ikhowuni eguqulweyo yenxalenye yokusika inkulu kakhulu.

4. I-reamer iyatshintsha kwi-gap kumngxuma ophakathi.

5.Xa ukuvuselelwa kwesandla, amandla agqithisileyo asetyenziswa kwicala elinye, ukunyanzela i-reamer ukuba ijikeleze kwicala elinye, yonakalise i-degrees ezi-5 ezithe nkqo zokubuyisela kwakhona.

Amanyathelo okuphendula

1. Yandisa inkqubo yokwandisa okanye imingxuma ekruqulayo ukulungisa imingxuma.

2. Nciphisa i-engile yokuphambuka ephambili.

3. Lungisa i-reamer efanelekileyo.

4. Buyisela i-reamer ngenxalenye ekhokelayo okanye inxalenye yokusika eyandisiweyo.

4. Ukwandisa indawo yokungena

isizathu

1. Ixabiso loyilo lwe-diameter yangaphandle ye-reamer likhulu kakhulu okanye kukho i-burrs kwi-cut cut ye-reamer.

2. Isantya sokusika siphezulu kakhulu.

3. Ireyithi yokutya engafanelekanga okanye isibonelelo somatshini esigqithisileyo.

4. I-angle yokutenxa ephambili ye-reamer inkulu kakhulu;Umphindi ugobile.

5. Kukho i-chip lump efakwe kwi-cut cut of the hinge cutting.

6. Xa ukugaya, ukuphambuka kwe-swing ye-hinge cutting edge kudlula ukunyamezela.

7. Ukukhethwa kwe-Cutting fluid ayifanelekanga.

8. Xa ufaka i-reamer, umphezulu wesibambo se-cone awucocwanga ngamabala e-oyile okanye kukho ama-bumps kunye namanxeba kwi-cone surface.

9. Umsila we-flat of the taper handle unqanyuliwe kwaye uphazamisa i-taper ye-taper handle emva kokufakwa kwi-spindle isixhobo somatshini.

10. Umsonto ujijekile okanye iibheringi zokuphotha zikhululekile kakhulu okanye zonakele.

11. Ukudada kwe-reamer akuguquguquki.

12. Xa i-axis yahlukile kwi-workpiece kunye nokuphindaphinda kwesandla, amandla kwizandla zozibini azilingani, okubangela ukuba i-reamer iguqe ngasekhohlo nasekunene.

Amanyathelo okuphendula

1. Ixabiso loyilo lwe-diameter yangaphandle ye-reamer likhulu kakhulu okanye kukho i-burrs kwi-cut cut ye-reamer.

2. Isantya sokusika siphezulu kakhulu.

3. Ireyithi yokutya engafanelekanga okanye isibonelelo somatshini esigqithisileyo.

4. I-angle yokutenxa ephambili ye-reamer inkulu kakhulu;Umphindi ugobile.

5. Kukho i-chip lump efakwe kwi-cut cut of the hinge cutting.

6. Xa ukugaya, ukuphambuka kwe-swing ye-hinge cutting edge kudlula ukunyamezela.

7. Ukukhethwa kwe-Cutting fluid ayifanelekanga.

8. Xa ufaka i-reamer, umphezulu wesibambo se-cone awucocwanga ngamabala e-oyile okanye kukho ama-bumps kunye namanxeba kwi-cone surface.

9. Umsila we-flat of the taper handle unqanyuliwe kwaye uphazamisa i-taper ye-taper handle emva kokufakwa kwi-spindle isixhobo somatshini.

10. Umsonto ujijekile okanye iibheringi zokuphotha zikhululekile kakhulu okanye zonakele.

11. Ukudada kwe-reamer akuguquguquki.

12. Xa i-axis yahlukile kwi-workpiece kunye nokuphindaphinda kwesandla, amandla kwizandla zozibini azilingani, okubangela ukuba i-reamer iguqe ngasekhohlo nasekunene.

5. Kukho imiphetho kumphezulu womngxuma ongaphakathi

Isizathu

1. Isibonelelo sokubuyisela kwakhona ngokugqithisileyo.

2. I-angle yokusika ye-reamer inkulu kakhulu.

3. Umphetho wokusika we-reamer umxinwa kakhulu.

4. Kukho iipores, imingxuma yesanti, kunye ne-spindle runout ngokugqithiseleyo kumphezulu we-workpiece.

Amanyathelo okuphendula

1. Nciphisa isibonelelo sokufunda kwakhona.

2. Nciphisa i-angle yangasemva yecandelo lokusika.

3. Gaya ububanzi bebhanti ye-blade.

4. Khetha iindawo ezingenanto.

6. Umqheba owaphukileyo

Isizathu

1. I-remer inde kakhulu kwaye ayinakho ukuqina, okubangela ukungcangcazela ngexesha lokubuyisela kwakhona.

2. I-angle yokutenxa ephambili ye-reamer incinci kakhulu.

3. Ibhanti enqamlezileyo yehenjisi;Ukugqithiswa kwesibonelelo sokubuyisela kwakhona.

4. Kukho iinotshi kunye nemingxuma enqamlezileyo ebusweni bomngxuma ongaphakathi.

5. Kukho imingxuma yesanti kunye nemingxuma kumphezulu womngxuma.

6. Ibherethi yokusonta ikhululekile, ayinamkhono wesikhokelo, okanye indawo evulekileyo phakathi kwesixhobo sokuphotha kunye nomkhono wesikhokelo mkhulu kakhulu, okanye ngenxa yokufakelwa kwezinto zokusebenza ezinodonga olucekethekileyo.

7. I-clamp iqine kakhulu kwaye i-workpiece ikhubaza emva kokususwa.

Amanyathelo okuphendula

1. Ukunciphisa isantya sokusika.

2. Khetha Ukusika ulwelo ngokwezixhobo zokusetyenzwa.

3. Nciphisa i-angle ephambili yokuphambuka ngokufanelekileyo kwaye ugaye i-cut cut edge ngokuchanekileyo.

4. Nciphisa isibonelelo sokubuyisela kwakhona ngokufanelekileyo.

5. Ukuphucula ukuchaneka kunye nomgangatho wendawo yomngxuma ongaphantsi ngaphambi kokuba uphinde uphinde uphinde unyuse isibonelelo sokubuyisela kwakhona.

6. Gaya ububanzi bebhanti ye-blade.

7. Nciphisa inani lamazinyo kwi-reamer ngokwemeko ethile, ukwandisa indawo ye-chip yokubamba i-groove, okanye usebenzise i-reamer ene-angle inclination angle ukuqinisekisa ukususwa kwe-chip egudileyo.

8. Ukutshintsha rhoqo i-reamer kwaye ususe indawo yokugaya ngexesha lokugaya i-blade.

9. Ngexesha lokugaya, ukusetyenziswa, kunye nokuthuthwa kwe-reamer, amanyathelo okukhusela kufuneka athathwe ukuphepha ukungqubana.

10. Kwi-remer eyonakeleyo, sebenzisa i-oilstone ecolekileyo ukuyilungisa okanye ukuyibuyisela endaweni yayo.

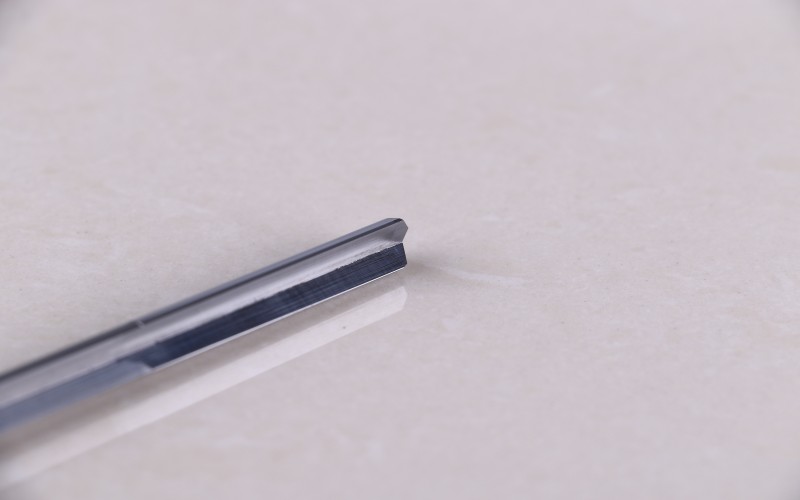

Ewe kunjalo, kuya kufuneka ube nomthengisi wesixhobo ogqwesileyo.Izixhobo zokusika ze-OPT ngumboneleli okumgangatho ophezulu okhethekileyo kwimveliso yemigangatho eyahlukeneyo / engeyiyo i-carbide reamerkwayePCD reamer

I-Shenzhen OPT Cutting Tool Co., Ltd. yenye yeemveliso eziphambili e-China, iingcali ekuphuhliseni nasekuveliseni izixhobo ze-carbides kunye ne-PCD yedayimani.

Ixesha lokuposa: Jun-16-2023