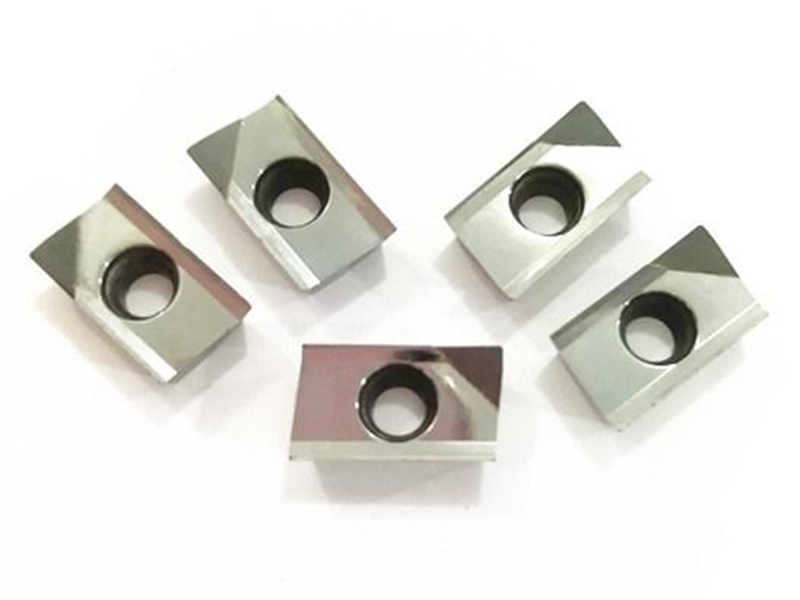

PCD Cutting Tool CNC Diamond Turning Milling Faka for aluminiyam

I-Milling PCD ifaka Ukusika izinto ezininzi

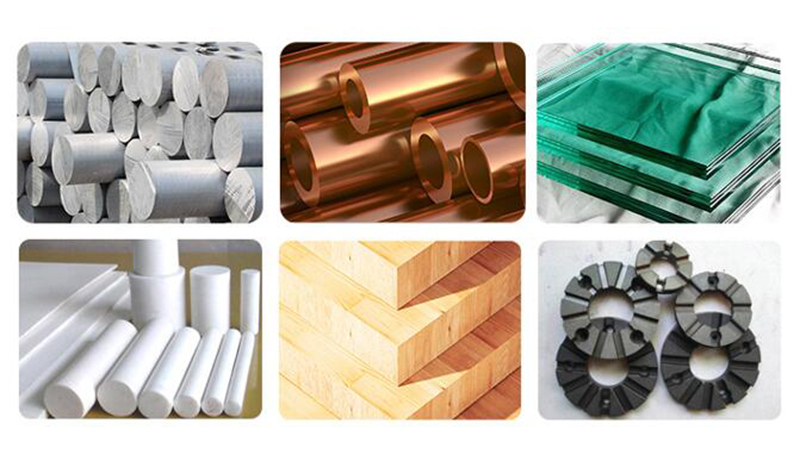

Ilungele ukusetyenzwa kweentsimbi ezingasebenziyo ezifana ne-aluminiyam kunye ne-aluminium alloys, i-alloys yobhedu kunye nobhedu, i-titanium, i-magnesium, i-zinc kunye nelothe.Ifayibha yeglasi, ifayibha yekhabhoni, iplastiki eyomeleziweyo kunye nezinye izinto ezingezizo ezentsimbi.

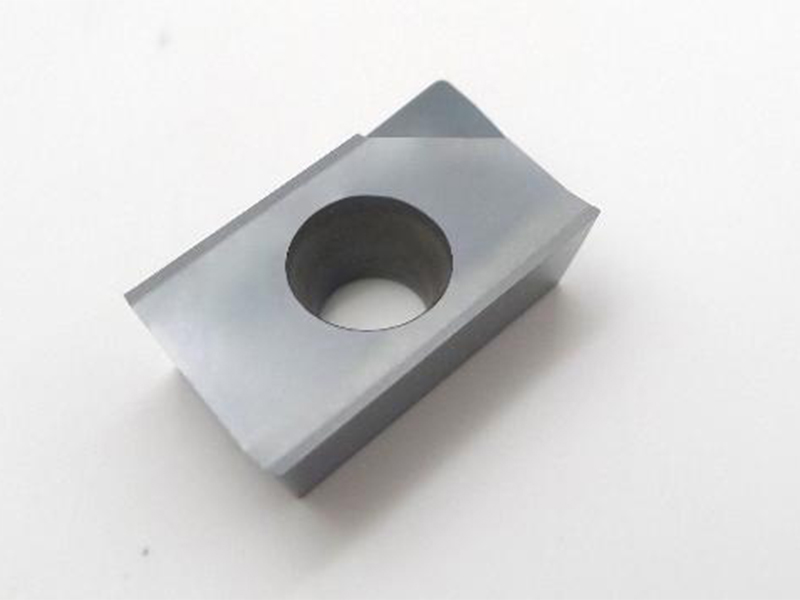

Khetha i-PCD yecala elipheleleyo elipheleleyo kwaye ufumane isiphumo esiphindwe kabini ngesiqingatha somzamo

Sebenzisa isiphumo se-OPT Ubuso obugcweleyo bokufaka i-PCD

1. Ixabiso eliphantsi lokucubungula

2. Ubomi benkonzo ende

3. Ukujika kunye nefuthe lokugaya likhanyayo

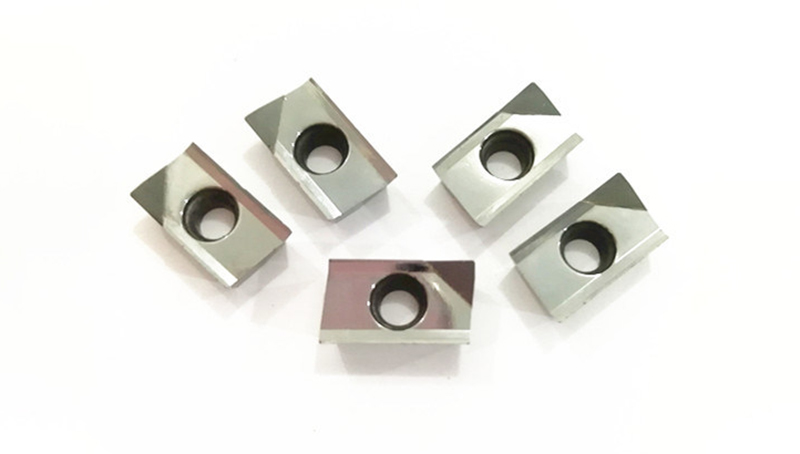

4. Ixesha elide eliqhubekayo lokucubungula I-OPT blade icutshungulwa ngokuqhubekayo imizuzu engama-400, kwaye i-blade idla ngokunxitywa ngaphandle kokuphuka.

Ukugqitywa kokusika okuphezulu, inkxaso yokwenza ngokwezifiso

Ngaphantsi kweemeko ezifanayo zokusika, inokunqumla ngokukhawuleza ngaphandle kokubambelela kwi-blade, ngokusebenza okuphezulu kunye nokugqiba okufunwayo.

I-blade inobunzima obuphezulu, ubukhali, ukuqina okulungileyo kunye nokumelana nokugqoka.Iindidi ezahlukeneyo kunye neenkcukacha, ezixhasa iinkcukacha ezilungiselelweyo.

Ukuhanjiswa okuphezulu kwe-thermal, ubomi benkonzo ende

I-thermal diffusivity ye-diamond cutter iphezulu, kwaye i-thermal conductivity yayo yi-1.5-9 ngamaxesha e-carbide ene-cemented kunye namaxesha angama-2-6 obhedu.Ukushisa okwenziwa ngokusika kulula ukuchithwa, kwaye ukushisa kwendawo yokusika isixhobo kuphantsi.Ubomi obude benkonzo.

Izinto ezikhethiweyo, ezomeleleyo kunye nencasa enkulu yePCD exhathisayo

Khetha umgangatho ophezulu we-PCD kunye ne-alloy eqinile kunye nokumelana nokunxiba ngamaxesha angama-60-80.Xa kusetyenzwa izinto ezinobunzima obuphezulu, ubomi bezixhobo zedayimani ngama-10-100 amaxesha ezixhobo ze-carbide ezinesamente, nokuba ngamakhulu amaxesha.

Ukulungiswa kwesantya esiphezulu, umthamo ophezulu wemveliso

Ukufakwa kwedayimani ye-PCD ifanelekile kwi-high-speed and dry machining.Zilukhetho lomatshini wanamhlanje wokuphucula ukusebenza kakuhle.Abakwazi nje ukwandisa imveliso yemihla ngemihla ngaphandle kotyalo-mali olongezelelweyo, kodwa basebenzise akukho manzi okusika.Zinobuhlobo nokusingqongileyo kwaye zithembekile.

Ukufunyanwa okungqongqo kunye nenkqubo engqongqo

1. Ukukhethwa kwezinto ezigqwesileyo kunye nokuhlolwa okungqongqo kwezinto ezibonakalayo ukuze kuqinisekiswe umgangatho ophezulu weemveliso ezigqityiweyo

2. Umtshina ophuma kumazwe angaphandle usebenzisa ngokungqongqo yonke inkqubo yemveliso ukuqinisekisa ukuba isiqwenga ngasinye semveliso sinokwanelisa kuwe.

| Ubungakanani, mm | |||||

| Uthotho | Umzekelo No. | d | S | d1 | R |

| SNGN | SNNG090304 | 9.525 | 3.18 | - | 0.4 |

| SNNG090308 | 9.525 | 3.18 | - | 0.8 | |

| SNNG090312 | 9.525 | 3.18 | - | 1.2 | |

| SNNG090316 | 9.525 | 3.18 | - | 1.6 | |

| SNGN120308 | 12.7 | 3.18 | - | 0.8 | |

| SNGN120312 | 12.7 | 3.18 | - | 1.2 | |

| SNGN120408 | 12.7 | 4.76 | - | 0.8 | |

| SNGN120412 | 12.7 | 4.76 | - | 1.2 | |

| Uthotho | Umzekelo No. | d | Sl | d1 | R |

| SNGA | SNGA090304 | 9.525 | 3.18 | 3.81 | 0.4 |

| SNGA090308 | 9.525 | 3.18 | 3.81 | 0.8 | |

| SNGA120404 | 12.7 | 4.76 | 5.16 | 0.4 | |

| SNGA120408 | 12.7 | 4.76 | 5.16 | 0.8 | |

| SNGA120412 | 12.7 | 4.76 | 5.16 | 1.2 | |

| Ubungakanani, mm | |||||

| Uthotho | Umzekelo No. | d | S | d1 | R |

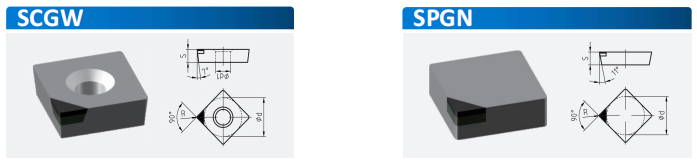

| SCGW | SCGW060202 | 6.35 | 2.38 | 2.2 | 0.2 |

| SCGW060204 | 6.35 | 2.38 | 2.2 | 0.4 | |

| SCGW090304 | 9.525 | 3.18 | 4.4 | 0.4 | |

| SCGW090308 | 9.525 | 3.18 | 4.4 | 0.8 | |

| I-SCGW09T304 | 9.525 | 3.97 | 4.4 | 0.4 | |

| I-SCGW09T308 | 9.525 | 3.97 | 4.4 | 0.8 | |

| SCGW120404 | 12.7 | 4.76 | 5.5 | 0.4 | |

| SCGW120408 | 12.7 | 4.76 | 5.5 | 0.8 | |

| Uthotho | Umzekelo No. | d | S | d1 | R |

| SPGN | SPN090304 | 9.525 | 3.18 | - | 0.4 |

| SPN090308 | 9.525 | 3.18 | - | 0.8 | |

| SPN090312 | 9.525 | 3.18 | - | 1.2 | |

| SPGN120304 | 12.7 | 3.18 | - | 0.4 | |

| I-SPGN120308 | 12.7 | 3.18 | - | 0.8 | |

| I-SPGN120312 | 12.7 | 3.18 | - | 1.2 | |

| I-SPGN120316 | 12.7 | 3.18 | - | 1.6 | |

| SPGN120408 | 12.7 | 4.76 | - | 0.8 | |

| I-SPGN120412 | 12.7 | 4.76 | - | 1.2 | |