1.Izixhobo zokusika izixhobo

Izixhobo eziqhelekileyo zesixhobo kwisixhobo sokusila zibandakanya: isinyithi esinesantya esiphezulu, isinyithi somgubo esinesantya esiphezulu, i-carbide ene-cemented, i-PCD, i-CBN, i-cermet kunye nezinye izinto ezinzima kakhulu.Izixhobo zentsimbi ezikhawulezayo zibukhali kwaye zinokuqina okuhle, ngelixa izixhobo ze-carbide zinobulukhuni obuphezulu kodwa zinzima.Ubuninzi bezixhobo ze-carbide ze-cemented ziphezulu kakhulu kunezixhobo zetsimbi ezikhawulezayo.Ezi zixhobo zimbini zezona zixhobo ziphambili kwi-drill bits, ii-reamers, ii-milling cutters kunye neetephu.Ukusebenza komgubo wesinyithi esinesantya esiphezulu kuphakathi kwezi zixhobo zimbini zingasentla, kwaye isetyenziswa ikakhulu ukwenza umsiki orhabaxa wokusila kunye nempompo.

Izixhobo zentsimbi ezikhawulezayo azikhathaleli ukungqubana ngenxa yokuqina kwazo okuhle.Nangona kunjalo, izixhobo ze-carbide ezine-cemented zinobunzima obuphezulu kunye ne-brittleness, zivakalelwa kakhulu xa zingqubana, kwaye umphetho kulula ukutsiba.Ngoko ke, kwinkqubo yokugaya, kuyimfuneko ukuba uqaphele kakhulu malunga nokusebenza kunye nokubekwa kwezixhobo ze-carbide eziqingqiweyo ukukhusela ukungqubana phakathi kwezixhobo okanye ukuwa kwezixhobo.

Ngenxa yokuba ukuchaneka kwezixhobo zentsimbi ezinesantya esiphezulu kuncinci, iimfuno zabo zokusila azikho phezulu, kwaye amaxabiso azo akaphezulu, abaninzi abavelisi bamisela izixhobo zabo zokusebenzela zokuzisila.Nangona kunjalo, izixhobo ze-carbide zesamente zihlala zifuna ukuthunyelwa kwiziko lokugaya elichwephesha lokugaya.Ngokwezibalo zamaziko amaninzi okugaya izixhobo, ngaphezu kwe-80% yezixhobo ezithunyelwe ukulungiswa zizixhobo ze-carbide ezifakwe ngesamente.

2. Ukusika Isixhobo sokusila

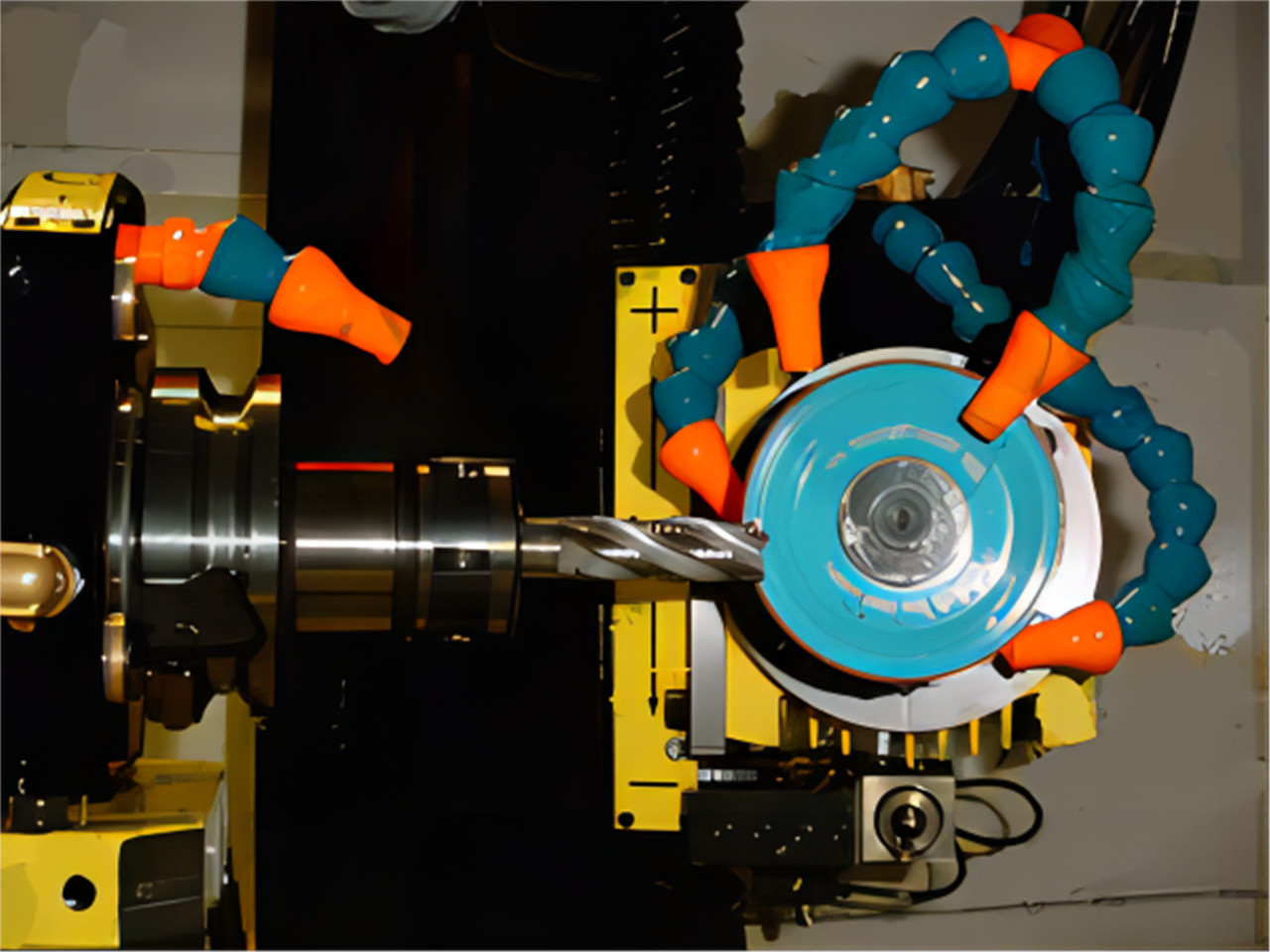

Ngenxa yokuba isixhobo sesixhobo sinzima kakhulu, sinokutshintshwa kuphela ngokusila.Izixhobo zokusila eziqhelekileyo ezisetyenziswa kwimveliso yezixhobo kunye nokusila ziquka oku kulandelayo:

(1).Umatshini wokuhlamba: ukugaya i-groove okanye umva we-drill bits, ii-mill end kunye nezinye izixhobo.

(2).I-Angle grinder: ukugaya i-angle ephezulu ye-conical (okanye i-eccentric back angle) ye-drill bit.

(3)

(4).I-Manual universal tool grinder: ukugaya isangqa sangaphandle, i-groove, umva, i-angle ephezulu, i-edge enqamlezayo, indiza, ubuso bangaphambili, njl.

(5).Umatshini wokusila we-CNC: ngokubanzi unxibelelwano lwe-axis emihlanu, kunye nemisebenzi egqitywe yi-software.Ngokuqhelekileyo isetyenziselwa izixhobo zokusila ezinobuninzi kunye neemfuno ezichanekileyo ezichanekileyo, kodwa azinzima, ezifana ne-drill bits, i-end Mills, i-reamers, njl. .

3.Ivili lokugaya

(1).Amasuntswana abrasive

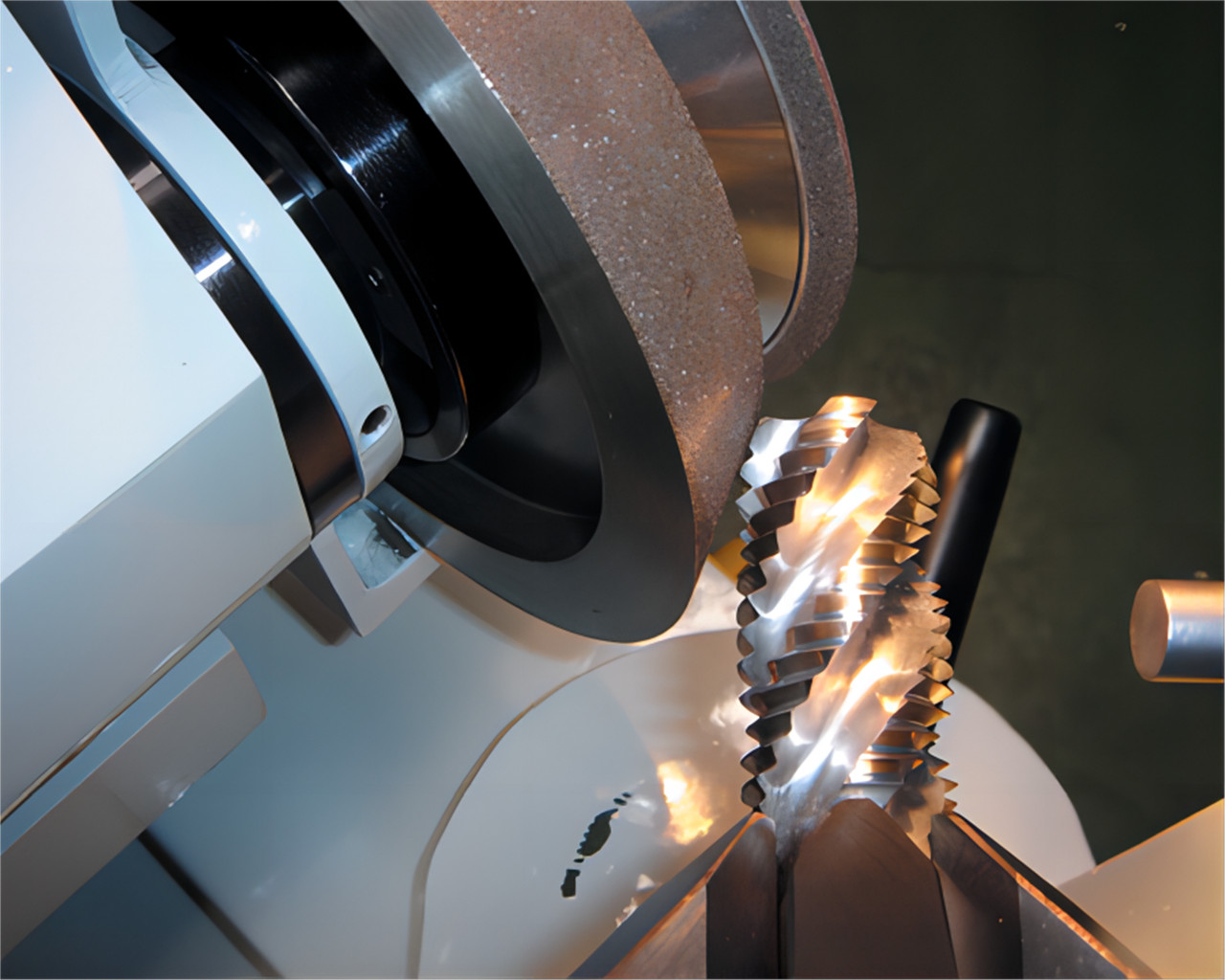

Ivili lokugaya i-particle abrasive particles of different materials zifanelekile izixhobo zokugaya izinto ezahlukeneyo.Izahlulo ezahlukeneyo zesixhobo zifuna ubukhulu obuhlukeneyo be-abrasive ukuze kuqinisekiswe ukuba udibaniso olungcono kakhulu lokukhusela umgca kunye nokusebenza kakuhle.

I-Alumina: isetyenziselwa ukugaya izixhobo ze-HSS.Ivili lokusila lixabiso eliphantsi kwaye kulula ukuba litshintshwe libe ziimo ezahlukeneyo zokusila izixhobo ezintsonkothileyo (corundum).

I-Silicon carbide: isetyenziselwa ukulungisa ivili lokusila le-CBN kunye nevili lokusila idayimane.

I-CBN (i-cubic boron carbide): isetyenziselwa ukugaya izixhobo ze-HSS.Ixabiso eliphezulu, kodwa ixesha elide.

Ngamazwe ngamazwe, ivili lokusila limelwe ngu-B, njenge-B107, apho i-107 imele ubukhulu be-abrasive particle diameter.

Idayimani: Isetyenziselwa ukugaya izixhobo ze-HM.Iyabiza kodwa yomelele.

(2).Ubume

Ukuze kube lula ukugaya iindawo ezahlukeneyo zesixhobo, ivili lokugaya kufuneka libe nemilo eyahlukeneyo.Ezona zisetyenziswa kakhulu zezi:

Ivili lokugaya elihambelanayo (1A1): i-angle ephezulu yokugaya, i-diameter yangaphandle, umva, njl.

Ivili lokusila elidityanisiweyo (12V9, 11V9): ukugaya i-spiral groove, ikona eziphambili kunye nezincedisi zokusika ze-milling cutter, ukucheba umda othe tye, njl.

Emva kokuba ivili lokugaya lisetyenziswe ixesha elithile, ukuma kwayo (kubandakanya indiza, i-angle kunye ne-fillet R) kufuneka ilungiswe.Ivili lokusila kufuneka lisoloko lisebenzisa ilitye lokucoca ukususa iitshiphusi ezizaliswe phakathi kweenkozo ezirhabaxa ukuphucula isakhono sokugaya ivili lokugaya.

4.Umgangatho wokugaya

Ingaba kukho isethi elungileyo yemigangatho yokugaya isixhobo ngumgangatho wokulinganisa ukuba iziko lokugaya liyingcali.Kumgangatho wokugaya, iiparitha zobugcisa becala lokusika izixhobo ezahlukeneyo xa usika izinto ezahlukeneyo zichazwe ngokubanzi, kubandakanywa i-angle of inclination, i-angle ephezulu, i-angle yangaphambili, i-angle yangasemva, i-chamfer, i-chamfer kunye nezinye iiparitha (kwi-carbide bit). , inkqubo yokugqithisa umgca wokusika ibizwa ngokuba yi "chamfer", kwaye ububanzi be-chamfer buhambelana nezinto eziza kunqunyulwa, ngokubanzi phakathi kwe-0.03-0.5Mm kunye ne-0.25Mm. Inkqubo ye-chamfering kwi-edge (inqaku lesixhobo) ibizwa ngokuba yi "chamfer" Inkampani nganye yobuchwephesha inemigangatho yayo yokusila eshwankathelweyo ngokuhamba kweminyaka.

Umahluko phakathi kwe bit HM kunye ne HSS bit:

I-HSS bit: i-engile ephezulu idla ngokuba yi-118 degrees, ngamanye amaxesha inkulu kune-130 degrees;Incakuba ibukhali;Iimfuno zokuchaneka (umahluko wobude be-blade, i-symmetry, ukuphuma kwe-circumferential runout) ziphantsi kakhulu.Kukho iindlela ezininzi zokulungisa i-blade ethe tye.

I-HM bit: i-engile ephezulu ngokuqhelekileyo i-140 degrees;Ii-slot drills zikholisa ukuba ngama-130 degrees, kwaye ii-drill ezintathu-edge ngokuqhelekileyo ziyi-150 degrees.I-blade kunye nencam (emphethweni) azibukhali kwaye zihlala zigqithiswa, okanye zibizwa ngokuba yi-chamfer kunye ne-chamfer;Ifuna ukuchaneka okuphezulu.Iblade ethe tyaba isoloko isikwe ibeyimilo ka-S ukuququzelela ukwaphuka kwetshiphu.

I-angle yangasemva: I-angle yangasemva ye-blade ibaluleke kakhulu kwisixhobo.Ikona yangasemva inkulu kakhulu, kwaye i-blade kulula ukutsiba kunye "nokugwaza";Ukuba i-angle yangasemva incinci kakhulu, ukungqubuzana kuya kuba kukhulu kakhulu kwaye ukusika kuya kuba yinto engathandekiyo.

I-angle yangasemva yesixhobo iyahluka kunye nezinto eziza kunqunyulwa kunye nohlobo kunye nobubanzi besixhobo.Ngokuqhelekileyo, i-angle yangasemva iyancipha ngokunyuka kwedayamitha yesixhobo.Ukongezelela, ukuba izinto eziza kunqunyulwa zinzima, i-angle yangasemva iya kuba yincinci, ngaphandle koko, i-angle yangasemva iya kuba nkulu.

5.Ukusika izixhobo zokubona izixhobo

Izixhobo zokubona izixhobo zokusika zihlulwe ngokubanzi zibe ziindidi ezintathu: isixhobo sokubeka isixhobo, iprojektha kunye nesixhobo sokulinganisa isixhobo jikelele.Isixhobo sokumisela isixhobo sisetyenziselwa ukulungiswa kwesixhobo (njengobude) bezixhobo ze-CNC ezifana namaziko omatshini, kunye nokufumanisa iiparitha ezifana ne-angle, i-radius, ubude besinyathelo, njl.Umsebenzi weprojektha ukwasetyenziselwa ukukhangela iiparameters ezifana ne-angle, i-radius, ubude besinyathelo, njl. Nangona kunjalo, ezi zimbini zingasentla azikwazi ukulinganisa i-angle yangasemva yesixhobo.Isixhobo sokulinganisa isixhobo somhlaba wonke sinokulinganisa uninzi lweeparamitha zejometri zesixhobo, kubandakanywa ne-angle yangasemva.

Ke ngoko, iziko lokugaya izixhobo zobuchwephesha kufuneka lixhotyiswe ngesixhobo sokulinganisa isixhobo jikelele.Nangona kunjalo, bambalwa ababoneleli bezixhobo ezinjalo, kwaye kukho iimveliso zaseJamani kunye nesiFrentshi kwimarike.

6.Igcisa lokusila

Esona sixhobo sibalaseleyo sikwafuna abasebenzi ukuze basebenze, kwaye uqeqesho lwamagcisa okusila ngokwemvelo lolona khonkco lubalulekileyo.Ngenxa yeshishini lokuvelisa izixhobo elibuyela ngasemva e-China kunye nokunqongophala okukhulu koqeqesho lobugcisa kunye nobugcisa, ukuqeqeshwa kwamagcisa okugaya izixhobo kunokusombulula kuphela ishishini ngokwalo.

7. Isiphelo

Ngezixhobo zokugaya, izixhobo zokuvavanya kunye nezinye i-hardware kunye nemigangatho yokugaya, amagcisa okugaya kunye nezinye isofthiwe, ukugaya izixhobo ezichanekileyo kunokuqala.Ngenxa yobunzima bokusetyenziswa kwesixhobo, iziko lokugaya elichwephesha kufuneka liguqule kwangexesha isicwangciso sokusila ngokwefom yokungaphumeleli kwesixhobo esiza kusila, kwaye silandele isiphumo sokusetyenziswa kwesixhobo.Iziko lobuchwephesha lokusila kufuneka lihlale lishwankathela amava ukwenza isixhobo sokugaya sibe ngcono kwaye sinobuchule ngakumbi!

Ixesha lokuposa: Feb-24-2023