Okwangoku, ishishini laseTshayina lokulungisa oomatshini likhula ngokukhawuleza, kwaye ezinye izinto ekunzima ukuzisika zisetyenziswa ngokubanzi kushishino lwemathiriyeli kunye neshishini lomatshini oluchanekileyo.Ukuze kuhlangatyezwane neemfuno zophuhliso lweshishini lokulungisa oomatshini bale mihla, kufuneka sisebenzise izixhobo ezithile ezinamandla aphezulu kunye nokuqina okuhle.Ngoko ke, izixhobo zezixhobo ezinzima zisetyenziswa ngokuthe ngcembe kumashishini okulungisa oomatshini.Eli nqaku ligxininise ekusetyenzisweni kwezixhobo zezixhobo ezinzima kwi-machining kwimbono yokuphuhliswa kwezixhobo eziphathekayo ezinzima, ukwenzela ukubonelela ngokubhekiselele kubahlobo kwishishini elifanayo.

Ngophuhliso olukhawulezayo lwetekhnoloji yokuvelisa yale mihla kunye nokhuphiswano oluqatha lwentengiso, iimfuno zeshishini lokwenziwa koomatshini kwiindawo zezixhobo zoomatshini nazo ziyanda, ngakumbi ekusebenzeni kolwakhiwo lwamalungu oomatshini.Ke ngoko, izinto ezintsha ezineempawu ezahlukeneyo ziye zavela ngokuthe ngcembe kuluntu.Ezi zixhobo zitsha azibangeli umceli mngeni omkhulu kuphela kwizixhobo zemveli zoomatshini, kodwa zikwanzima kakhulu ukuziqhuba.Ngeli xesha, izixhobo zokusika eziphambili ziye zaba ngundoqo ekuphuhliseni ishishini lokucubungula ngoomatshini, kwaye izixhobo zezixhobo ezinzima ngokungathandabuzekiyo zisetyenzisiwe kumatshini wanamhlanje.

1. Imbali yophuhliso lwezixhobo zokusebenza ezinzima

Ngeminyaka yoo-1950, izazinzulu zaseMelika zathatha idayimane yokwenziwa, ibhondi, kunye ne-boron carbide powder njengezinto ezikrwada, zasabela phantsi kobushushu obuphezulu kunye noxinzelelo, kunye nebloko ye-polycrystalline sintered njengeyona nto iphambili yesixhobo.Emva kweminyaka yoo-1970, abantu ngokuthe ngcembe baphuhlisa imathiriyeli yamaphepha edityanisiweyo, eveliswa ngokudibanisa idayimani kunye nekhabhide enesamente, okanye i-boron nitride kunye ne-samente carbide.Kule teknoloji, i-carbide ene-cemented ithathwa njenge-substrate, kwaye uluhlu lwedayimane lwenziwa phezu kwe-substrate ngokucinezela okanye ukucoca.Idayimani imalunga ne-0.5 ukuya kwi-1 mm ubukhulu.Izinto ezinjalo azikwazi nje ukuphucula ukunyanzeliswa kokugoba kwezinto, kodwa kunye nokusombulula ngokufanelekileyo ingxaki yokuba izinto zemveli azilula ukuba zidibanise.Oku kukhuthaze isixhobo sezinto ezinzima ukungena kwinqanaba lesicelo.

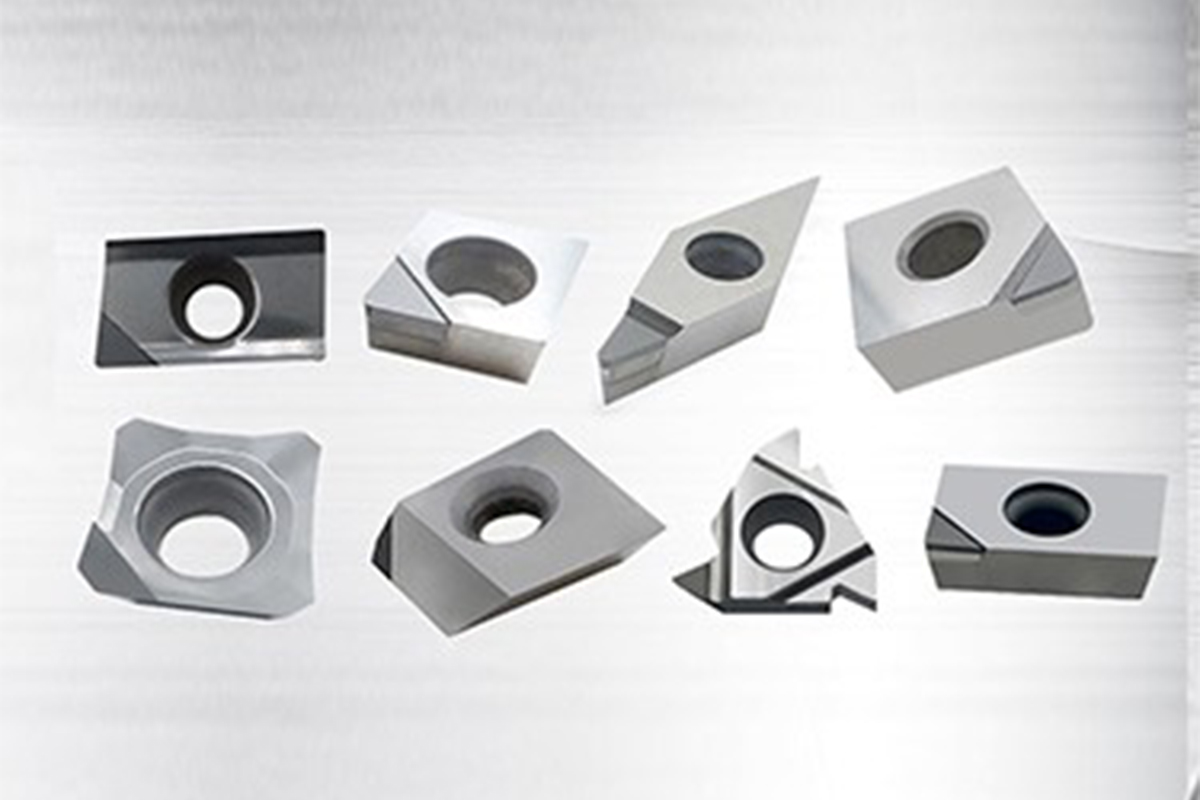

2. Ukusetyenziswa kwezixhobo zezixhobo ezinzima kumatshini

(1) Ukusetyenziswa kwezixhobo zedayimani enye yekristale

Idayimani enye yekristale ihlala yohlulwe kwidayimani yokwenziwa kunye nedayimani yendalo.Ngokubanzi, ukuba idayimani enye yekristale isetyenziselwa ukwenza isixhobo, kuyafuneka ukuba ukhethe idayimani enobungakanani besuntswana elikhulu, ubunzima obungaphezulu kwe-0.1 g kunye nobude obungaphezulu kwe-3 mm.Okwangoku, idayimani yendalo yeyona nto inzima kwiiminerali.Ayinayo nje into elungileyo yokumelana nokunxiba, kodwa nesixhobo esenziwe ngayo sibukhali kakhulu.Ngelo xesha, inokumelana nokubambelela okuphezulu kunye ne-conductivity ephantsi ye-thermal.Isixhobo esenziwayo sigudileyo kwaye sikumgangatho olungileyo.Kwangaxeshanye, isixhobo esenziwe ngedayimane yendalo sinokuqina okuhle kakhulu kunye nobomi benkonzo ende.Ukongeza, xa usikwa ixesha elide, kuya kuba nzima ukuchaphazela ukusetyenzwa kwamalungu.I-conductivity ephantsi ye-thermal inokuba nefuthe elihle ekuthinteleni ukuguqulwa kwamalungu.

Idayimani yendalo ineenzuzo ezininzi.Nangona ezi zibonelelo zibiza kakhulu, ziyakwazi ukuhlangabezana neemfuno zemisebenzi emininzi yokusika echanekileyo kwaye isetyenziswa ngokubanzi ekusikeni ngokuchanekileyo kunye nokusika kwe-ultra-precision.Njengokubonisa izibuko ezisebenzisa iathom yeathom kunye nobunye ubugcisa obuphambili, kunye neegyroscopes zokuhamba emhlabeni ezisetyenziswa kwimijukujelwa okanye iirokethi, kunye nezinye iindawo zokubukela, izixhobo zentsimbi, njl.

(2) Ukusetyenziswa kwezixhobo zedayimane ze-polycrystalline

Idayimani yePolycrystalline idla ngokubizwa ngokuba yidayimani edibeneyo.Ukusetyenziswa kwedayimane ye-polycrystalline kwiintsimbi ezifana ne-cobalt, ngobushushu obuphezulu kunye neemeko zoxinzelelo oluphezulu, kuya kwenza i-diamond eninzi ye-crystalline powder polycrystalline ibe yinto enye, ngaloo ndlela yenze izixhobo ze-polycrystalline.Ukuqina kwedayimane ye-polycrystalline ingaphantsi kunobo bedayimane yendalo.Nangona kunjalo, yenziwe ngeentlobo ezahlukeneyo ze-diamond powder, kwaye akukho meko yokuba iindiza zekristale ezahlukeneyo zinamandla ahlukeneyo kunye nobunzima.Xa usika, umgca wokusika owenziwe ngedayimane ye-polycrystalline unokumelana okuphezulu kakhulu nomonakalo wengozi kunye nokumelana nokunxiba kakuhle.Iyakwazi ukugcina i-cut cut ibukhali ixesha elide.Kwangaxeshanye, inokusebenzisa isantya esikhawulezayo sokusika xa kusetyenzwa.Xa kuthelekiswa nezixhobo ze-carbide ezenziwe ngesamente zeWC, izixhobo zedayimane ezine-polycrystalline zinobomi obude benkonzo, ukufikelela lula kwizinto zokwenziwa kunye namaxabiso aphantsi.

(3) Ukusetyenziswa kwedayimani yeCVD

Isixhobo sedayimani ye-CVD sicutshungulwa phantsi koxinzelelo oluphantsi, owona mahluko mkhulu kubuchwepheshe be-PSC bemveli kunye nobuchwepheshe bePDC.Idayimani ye-CVD ayiqulathanga naliphi na ilungu le-catalyst.Nangona ifana nedayimane yendalo kwezinye iipropathi, isafana nedayimane ye-polycrystalline kwizinto eziphathekayo, oko kukuthi, iinkozo zokwakheka zicwangciswe ngocwangco, ukungabikho komphezulu we-brittle cleavage, kwaye zineepropati ezifanayo phakathi kwemiphezulu.Xa kuthelekiswa nezixhobo ezenziwe ngobuchwephesha bemveli, izixhobo ezenziwe yi-CVD iteknoloji yedayimani zineenzuzo ezininzi, ezifana nokumila kwesixhobo esintsonkothileyo, iindleko ezisezantsi zokuvelisa, kunye neencakuba ezininzi zeblade efanayo.

(4) Ukusetyenziswa kwe-polycrystalline cubic boron nitride

I-Polycrystalline cubic boron nitride (PCBN) sisixhobo esixhaphake kakhulu sezinto eziphathekayo, esisetyenziswa ngokubanzi nangakumbi kwi-machining.Isixhobo esenziwe ngobu buchwepheshe sinobunzima obubalaseleyo kunye nokumelana nokunxiba.Ayinakusetyenziswa kuphela kumaqondo obushushu aphezulu, kodwa inokumelana ne-corrosion egqwesileyo kunye ne-thermal conductivity.Xa kuthelekiswa nezixhobo ze-PCD kunye ne-PDC, izixhobo ze-polycrystalline cubic boron nitride zisengaphantsi kokumelana nokunxiba, kodwa zinokusetyenziswa ngokuqhelekileyo kwi-1200 ℃ kwaye ziyakwazi ukumelana nokubola kweekhemikhali ezithile!

Okwangoku, i-polycrystalline cubic boron nitride isetyenziswa ikakhulu kwimveliso yeemoto, ezinje ngeenjini zemoto, iishafti zothumelo, kunye neediski zeebhuleki.Ukongeza, malunga nesinye kwisihlanu sokulungiswa kwezixhobo ezinzima zisebenzisa obu buchwepheshe.Kwiminyaka yakutshanje, kunye nophuhliso lwetekhnoloji yekhompyuter kunye nobuchwepheshe besixhobo somatshini we-CNC, ukusetyenziswa kwe-polycrystalline cubic boron nitride kuye kwanda kakhulu, kunye nokuphunyezwa kweengqikelelo eziphambili zomatshini ezifana nokusika ngesantya esiphezulu, ukujika endaweni yokugaya, isixhobo. Izinto ze-polycrystalline cubic boron nitride ziye zakhula ngokuthe ngcembe zaba yinto ebalulekileyo ekuguquleni kwangoku.

3. Isishwankathelo

Ukusetyenziswa kwezixhobo zezixhobo ezilukhuni kwi-machining akugcini nje ukuphucula umgangatho kunye nokusebenza kakuhle komatshini, kodwa kudlala indima ebalulekileyo ekuphuhliseni ishishini lokucubungula oomatshini.Ngoko ke, ukuze kukhuthazwe uphuhliso lweshishini lokulungisa oomatshini, kuyimfuneko ukuba ngokuqhubekayo ukomeleza uphando lwezixhobo eziphathekayo ezinzima, ukuqonda ngokupheleleyo ulwazi olunxulumene nezixhobo eziphathekayo, kunye nokomeleza umkhuba wokwenza isicelo, kungekhona nje ukuphucula umgangatho wezinto eziphathekayo. abasebenzi, kodwa nokomeleza ukusetyenziswa kwenzululwazi kunye neteknoloji ekuphuculeni izixhobo zemathiriyeli enzima, ukuze kuphuhliswe uphuhliso lwe-leapfrog yoshishino lokulungisa oomatshini.

Ixesha lokuposa: Jun-03-2019