CNC ukucofa Impompo yefluti ethe tye Itephu yekhabhide eqinileyo yempompo yokupholisa yentsimbi

- Ingcaciso yeMveliso

Kubasebenzisi abaneemeko zokusebenzisa isipholileyo ngexesha lokusetyenzwa, impompo ye-carbide epholileyo yangaphakathi inokuxhotyiswa ukuphucula ubomi besixhobo.

I-OPT ibonelela ngeempompo ze-carbide ezipholileyo zangaphakathi kunye neetephu zokupholisa ezisecaleni, oko kuxhomekeke kwisicelo sabasebenzisi.

imingxuma yokupholisa isebenza injongo ebalulekileyo ekwandiseni ubomi besixhobo seempompo zekhabhide.

Okokuqala, imingxuma yangaphakathi yokupholisa iqondisa isisipholisi ngokuthe ngqo kwincam yokusika, inciphisa ubushushu bokusika kunye nokukhuhlana.Oku akuncedi kuphela ekuthinteleni ukushisa okugqithisileyo kwempompo kodwa kukwaphucula ukufuduswa kwetshiphu.

Okwesibini, ubukho bemingxunya yokupholisa esecaleni busasaza into epholileyo ejikeleze i-tap shank, kunciphisa ngakumbi ukwakheka kobushushu kunye nobomi bempompo.

- Usetyenziso oluqhelekileyo

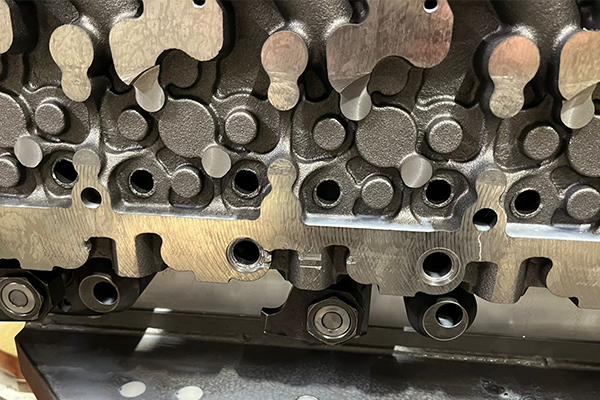

Olunye usetyenziso oluqhelekileyo lwempompo ye-carbide kumatshini wokwenza iintloko zeesilinda ze-injini yentsimbi.Ezi ntloko ze-cylinder zidlala indima ebalulekileyo ekusebenzeni ngokubanzi kunye nokuqina kweenjini.Ngokusetyenziswa kweempompo ze-carbide, abavelisi bafezekisa ukuchaneka okuphezulu kwentambo, okukhokelela kwiipropati zokutywinwa eziphuculweyo kunye nokunciphisa amathuba okuvuza.Ngaphezu koko, ubomi besixhobo esandisiweyo seempompo ze-carbide zenza imveliso yobuninzi esebenzayo ngelixa igcina imigangatho yomgangatho engaguqukiyo.

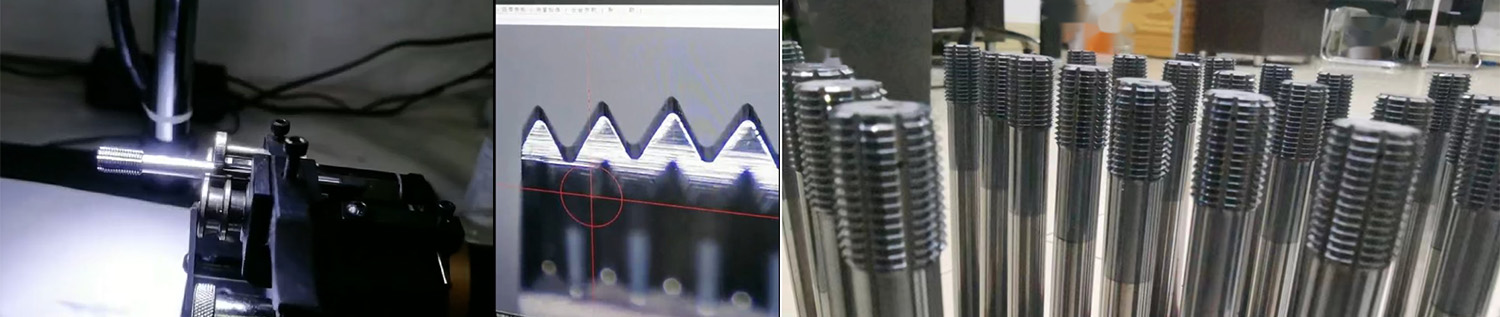

Ukuhlolwa kunye nomboniso

Ngaphambi koku-odola, nceda unxibelelane nenkonzo yethu yabathengi yangaphambi kokuthengisa:

1. Izinto eziphathekayo

2. Ingaba imveliso iphathwa kumphezulu emva kokulungiswa

3. Iimfuno zokuchaneka, ubungakanani begeji ye-go kunye ne-go gauge.

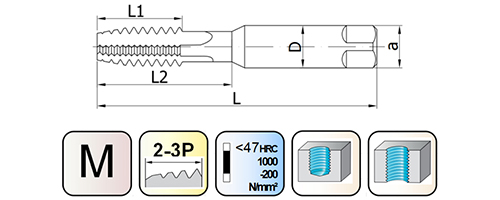

| Ubizo D | Ubungakanani bomsonto | Ukubetha mm | L1 mm | L2 mm | D mm | L mm | Z | a ¨ | I-pre-drill mm |

| T602-040048-M3x0.5 | M3 | 0.5 | 11 | 18 | 4 | 48 | 4 | 3.15 | 2.46-2.59 |

| T602-040050-M3.5×0.6 | M3.5 | 0.6 | 13 | 21 | 4 | 50 | 4 | 3.15 | 2.85-3.01 |

| T602-050053-M4x0.7 | M4 | 0.7 | 13 | 21 | 5 | 53 | 4 | 4 | 3.25-3.42 |

| T602-060058-M5x0.8 | M5 | 0.8 | 16 | 25 | 6 | 58 | 4 | 4.5 | 4.14-4.33 |

| T602-060066-M6x1 | M6 | 1 | 19 | 30 | 6 | 66 | 4 | 4.5 | 4.92-5.15 |

| T602-080072-M8x1 | M8 | 1 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.92-7.15 |

| T602-080072-M8x1.25 | M8 | 1.25 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.65-6.91 |

| T602-080080-M10x1 | M10 | 1 | 24 | - | 8 | 80 | 4 | 6.3 | 8.92-9.16 |

| T602-100080-M10x1 | M10 | 1 | 24 | 38 | 10 | 80 | 4 | 8 | 8.92-9.16 |

| T602-080080-M10x1.25 | M10 | 1.25 | 24 | - | 8 | 80 | 4 | 6.3 | 8.65-8.91 |

| T602-100080-M10x1.25 | M10 | 1.25 | 24 | 38 | 10 | 80 | 4 | 8 | 8.65-8.91 |

| T602-080080-M10x1.5 | M10 | 1.5 | 24 | - | 8 | 80 | 4 | 6.3 | 8.38-8.67 |

| T602-100080-M10x1.5 | M10 | 1.5 | 24 | 38 | 10 | 80 | 4 | 8 | 8.38-8.67 |

| T602-100089-M12x1.25 | M12 | 1.25 | 29 | - | 10 | 89 | 4 | 8 | 10.65-10.91 |

| T602-120089-M12x1.25 | M12 | 1.25 | 29 | 46 | 12 | 89 | 4 | 10 | 10.65-10.91 |

| T602-100089-M12x1.5 | M12 | 1.5 | 29 | - | 10 | 89 | 4 | 8 | 10.38-10.67 |

| T602-120089-M12x1.5 | M12 | 1.5 | 29 | 46 | 12 | 89 | 4 | 10 | 10.38-10.67 |

| T602-100089-M12x1.75 | M12 | 1.75 | 29 | - | 10 | 89 | 4 | 8 | 10.11-10.44 |

| T602-120089-M12x1.75 | M12 | 1.75 | 29 | 46 | 12 | 89 | 4 | 10 | 10.11-10.44 |

| T602-120095-M14x1.5 | M14 | 1.5 | 30 | - | 12 | 95 | 4 | 10 | 12.38-12.67 |

| T602-120095-M14x2 | M14 | 2 | 30 | - | 12 | 95 | 4 | 10 | 11.84-12.2 |

| T602-120102-M16x2 | M16 | 2 | 32 | - | 12 | 102 | 4 | 10 | 13.9-14.2 |